PlasticExpress bridges the gap between a distributor and a processing company:

All of this results in savings of up to 50% compared to Western European suppliers.

We operate three laser plotters from the renowned German company Eurolaser, which allow us to cut any custom shape from plexiglass as specified by our clients. The high power of these machines enables cutting of materials up to 20 mm thick with exceptional precision—down to 0.3 mm accuracy. All machines can process entire plexiglass sheets up to 2000 x 3000 mm in size.

The process uses a concentrated beam of hot laser, a non-contact technology that minimizes the risk of material damage. During cutting, the plexiglass is cooled with compressed air to prevent ignition. Any trace amounts of chemicals released during melting are immediately absorbed by the extraction system, making our plotters environmentally friendly. The edges of the cut pieces are smooth, glossy, and aesthetically pleasing.

The FK6 330 panel saw from the Austrian company Schelling is the most advanced machine of its kind, guaranteeing cutting precision up to 0.1 mm over a 3-meter length. This machine is capable of cutting individual plastic sheets or processing batches with a total thickness of up to 100 mm. The cutting process is 99% dust-free which prevents sawdust from contaminating the panels. This method is the fastest way to cut plexiglass and polycarbonate sheets to your desired dimensions. The only limitation is that it can only cut at a 90° angle. The resulting edge becomes matte and slightly less refined compared to that produced by a laser cutter, but this is compensated by a lower price and faster order turnaround.

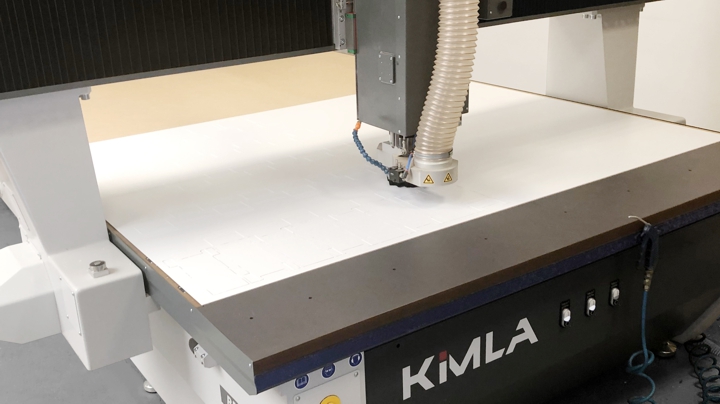

Kimla milling plotters enable us to cut any shape from polycarbonate sheets. Once the appropriate milling cutter is selected, the machine ensures fast and precise processing regardless of the material's thickness. The large work area allows us to process orders even on full sheets measuring up to 2000 x 3000 mm. In addition to cutting, the milling machine is also capable of chamfering edges and creating recesses or blind holes with specified depth and surface area.

We have two machines from the Spanish company Bermaq designed for polishing plexiglass using natural diamonds. Thanks to their unique construction, the material remains stationary during processing, which results in a higher quality finished edge. The technology allows for polishing elements up to 2000 mm in a straight line, meaning that only edges cut at a right angle can be polished—rounded edges and complex shapes are not possible.

Over 600,000 kg of raw material processed anually

Over 600,000 kg of raw material processed anually

Over 150 tons of sheets in constant availability from our warehouse

Over 150 tons of sheets in constant availability from our warehouse

35 years on plastic sheet market

35 years on plastic sheet market

Multi-shift production

Multi-shift production

5,000+ customers served anually

5,000+ customers served anually

20,000+ orders processed anually

20,000+ orders processed anually

The configurator may not work properly. To view this page correctly, Update your browser